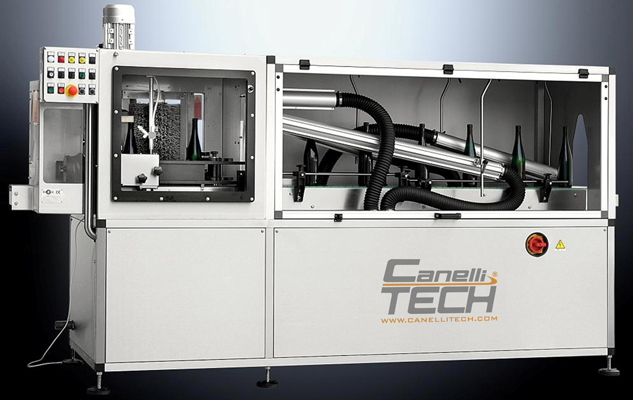

Canellitech Automatic Bottle washing drying machine

Production: from 1.000 bph to 6.000 bph

METHOD OF FUNCTION:

The washer/drying machine has been specifically designed for the external cleaning of filled bottles, this operation is completed in three stages, the first stage utilises high speed rotating brushes to clean the neck and bottom of the bottle

As the bottle approaches the second stage a presser unit holds the bottle in position on the bottle stool, the bottle is then rotated against the main brush, water is sprayed via adjustable nozzles optimising the cleaning process.

The bottle neck is then dried using compressed air.

Complete drying of the bottle is achieved with air knives affixed to the exit conveyor; the blown air is approximately 25/30°C higher than the ambient temperature.

The tower main frame is manufactured from protection coated mild steel with all external surfaces clad in AISI 304 stainless steel.

- h

More Info!